WARNING: 3D-ONE, is no longer available.

This product no longer in commerce.

Prices or other informations related to this product are not available.

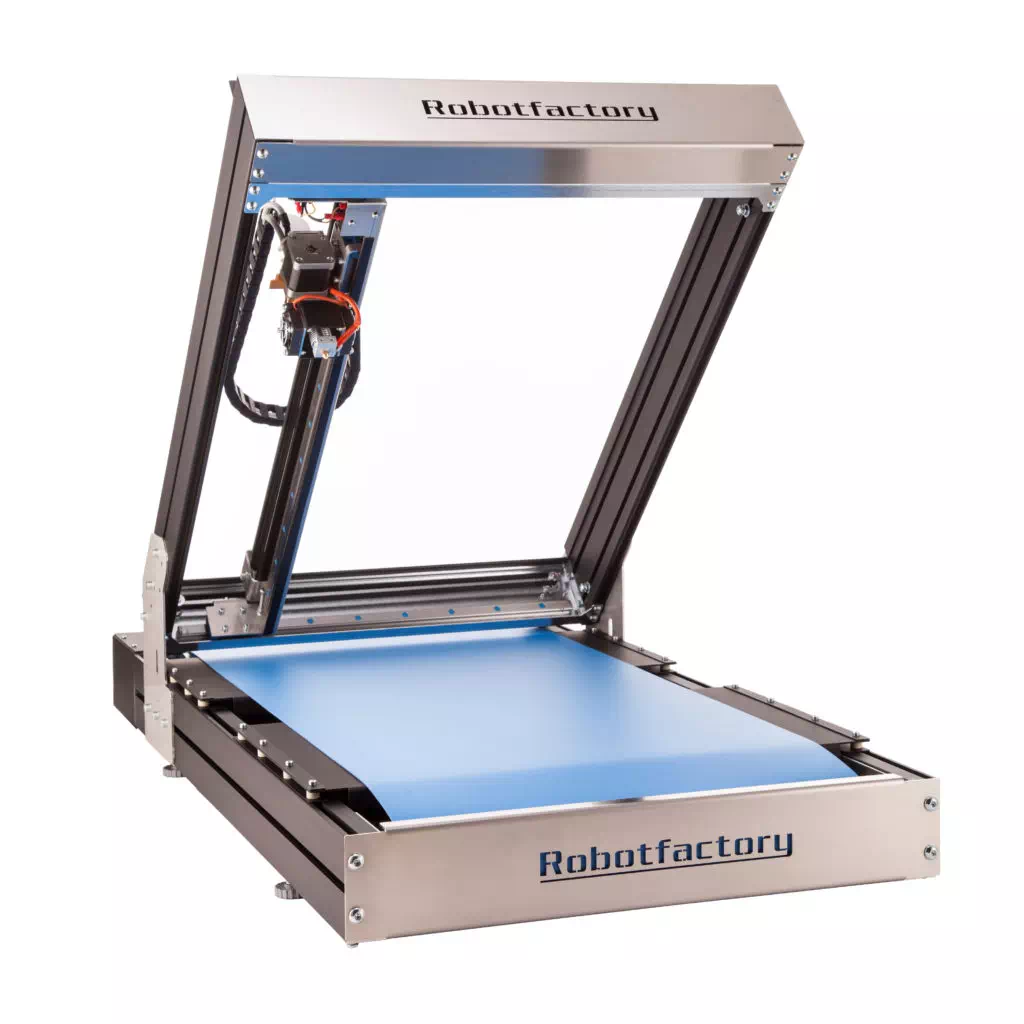

3D Printer FFM 3D-One : accuracy and performance in a mechanical structure of a high level

We know that is not easy to convert ideas into a physical and tangible geometry, especially into real objects; the Additive Manufacturing provides everyone the opportunity to do rapid prototyping low cost.

The possibilities offered today by Additive Manufacturing and 3D printer ONE are amazing, allows us to grasp these opportunities so quick and easy.

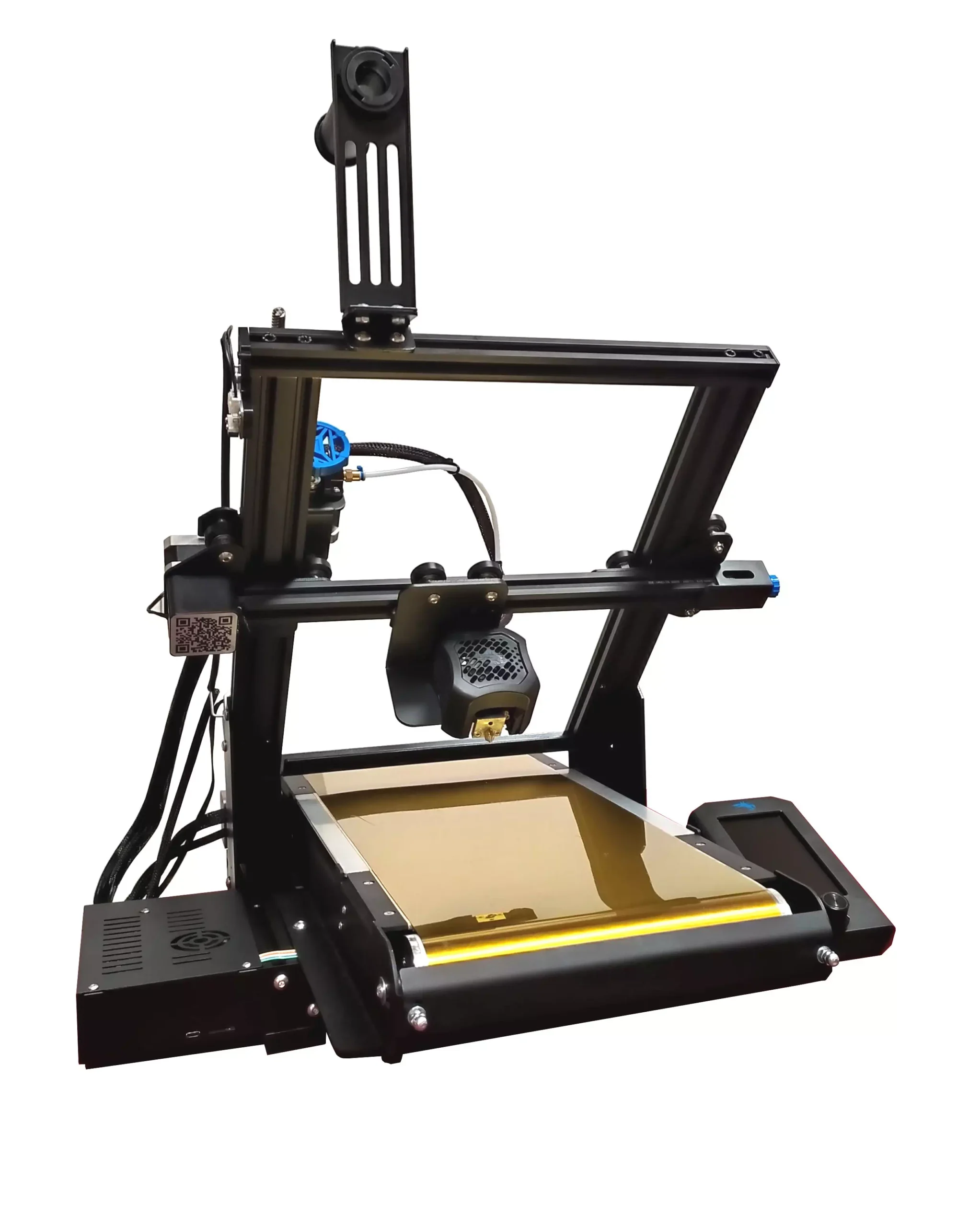

3D-ONE is the 3D printer, designed and produced by Robot Factory, which uses technology FDM, extrusion of thermoplastic material.

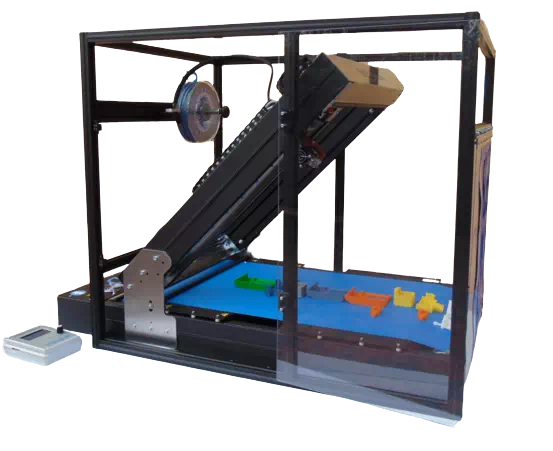

With 3D-ONE, the object is created for layers of material, the thread of thermoplastic material is heated in the extruder and through a particular mechanism is extruded from the nozzle, forming a thin wire that is placed layer upon layer to construct the object three-dimensional to realize.

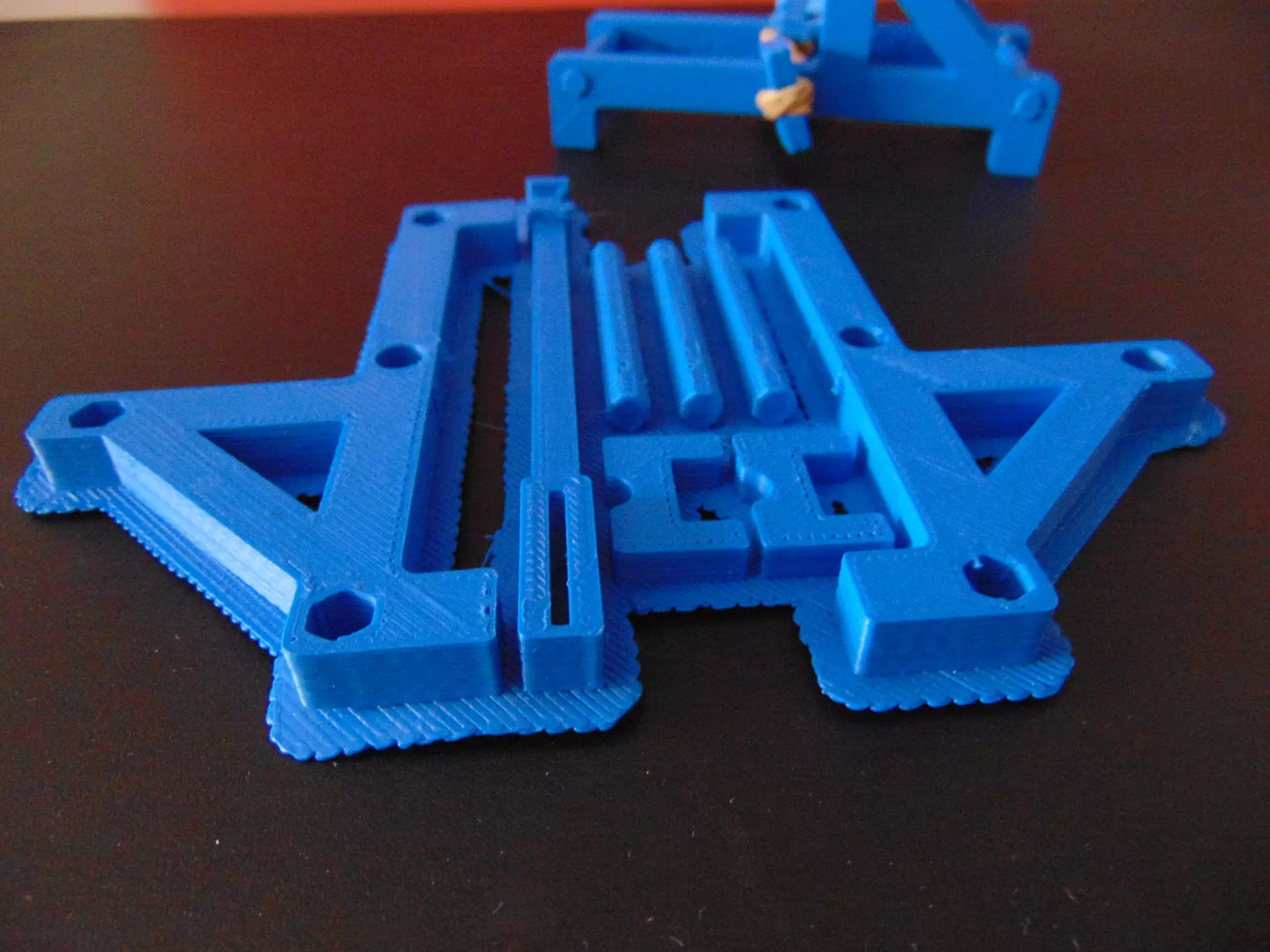

Make your 3D Models in plastic or composite like PLA, ABS, PC, PVA, ecc… comfort at your home, simple, fun and professional!

With the Printer 3D-ONE, manufacturers of small series and prototypes of the most different sectors may rely on a rapid and economic realization of three-dimensional models for the production of prototypes, using 3D CAD drawings.

Through the use of the 3D printer, the designer can easily try different test, optimize the design and through trial and error, he can make changes quickly and flexibly, he can touch the object in a very short time than in the past.

The Printer 3D–ONE operates not only fast, but also very accurately; the object is printed with a precision in the details, but also with the mechanical stability necessary for processing.

The object after printing is already available to be manipulated by the operator; it can be used directly to create the mold production in series, or if necessary, to optimize the quality of the surface. It is possible to paint the object or, using some small measure, it is possible to level the surface to obtain a result even more real.

It is clear that you can save time and money with this way of working.

With the 3D-ONE Printer, the 3D printing becomes accessible to designers and engineers who are looking for innovation and simplification of their work, all in a compact and quiet machine that can be placed in a corner of any workplace.

A large work space with 245 x 245 x 245mm and a resolution until 0.01 mm for the realization of your 3D models!

The 3D-One system allows to obtain layers of printing from 0.1 mm to produce models with high detail and with an accuracy of a professional level, for many applications, including the development and verification of the projects, the production of prototypes for tests footprint and assembly, as well as the product’s presentation to the customer.

The production of all digital objects and prototypes in plastic, unable to imagine today the fascinating possibilities that this technology opens up for the future, putting us on a totally new direction in the search for new creative horizons.

The fields of use of the 3D-One Printer are several:

- Designer – the designer has the possibility to control and find any flaws in the printed model before the final realization and to obtain forms unimaginable before.

- Art creation – artists and architects can create new forms working byself to create models and 3D objects to shows to their customers.

- Didacticts – the students can touch the shapes of complex geometries that until now were drawings only on the books, while teachers can make their lessons more interesting using objects printed in 3D.

- Medical industry – the 3D printer can produce realistic anatomical models and prototypes of medical devices surgical.

- Mechanical industry – the 3D Printer is a valuable support to create mechanical parts, for footprint tests and assembly, as well as the product’s presentation to the customer.

For every field, maybe, the function more interesting is sending a file in a mail to a coworker in another country so he can make in real time with his 3D-One Printer the 3D object, without delay or loss of time.

For the realization of the 3D object using a three-dimensional drawing in STL (Standard Tessellation Language) which is a native file format of all 3D CAD systems, so that you can draw, you can not print.

All materials can be used with 3D ONE, we especially can supply ABS (Acrylonitrile Butadiene Styrene) of high quality.

The ABS spools are available in various colors (white, black, red, blue, green, yellow, etc …)

3D-ONE uses the additive method, that is, the object is created by successive layers of material, the thread of thermoplastic material is heated by a resistance and is extruded by a particular mechanism from the nozzle, forming a thin wire that is place layer by layer to build the three-dimensional object.

- Technical Specifications

- Documents & Download

| Total dimensions | 600 x 500 x 660 mm without support material |

| Weight | 25 Kg approx without support material |

| Useful working dimensions | 245 x 245 x 245 mm |

| Work plan | 255 x 260 mm |

| Power supply | 230v – 300 watt approx |

| Heater | 50 watt – 24v (armored e protected) |

| Thermoregulation | Adjustable digital thermostat with thermocouple probe J |

| Max extruder temperature | 270 °C |

| Axis resolution X – Y | 0,06 mm |

| Axis resolution Z | 0,01 mm |

| Axis speed X – Y | 5.000 mm/min |

| Axis speed Z | 3.000 mm/min |

| Extruder speed | 2.000 mm/min |

| Slice | 0,10 / 0,21 / 0,31 / 0,42 / 0,53 (mm) |

| Nozzle supply | 0.48 mm (on request 0.37 / 0.39 / 0.42 / 0.53) |