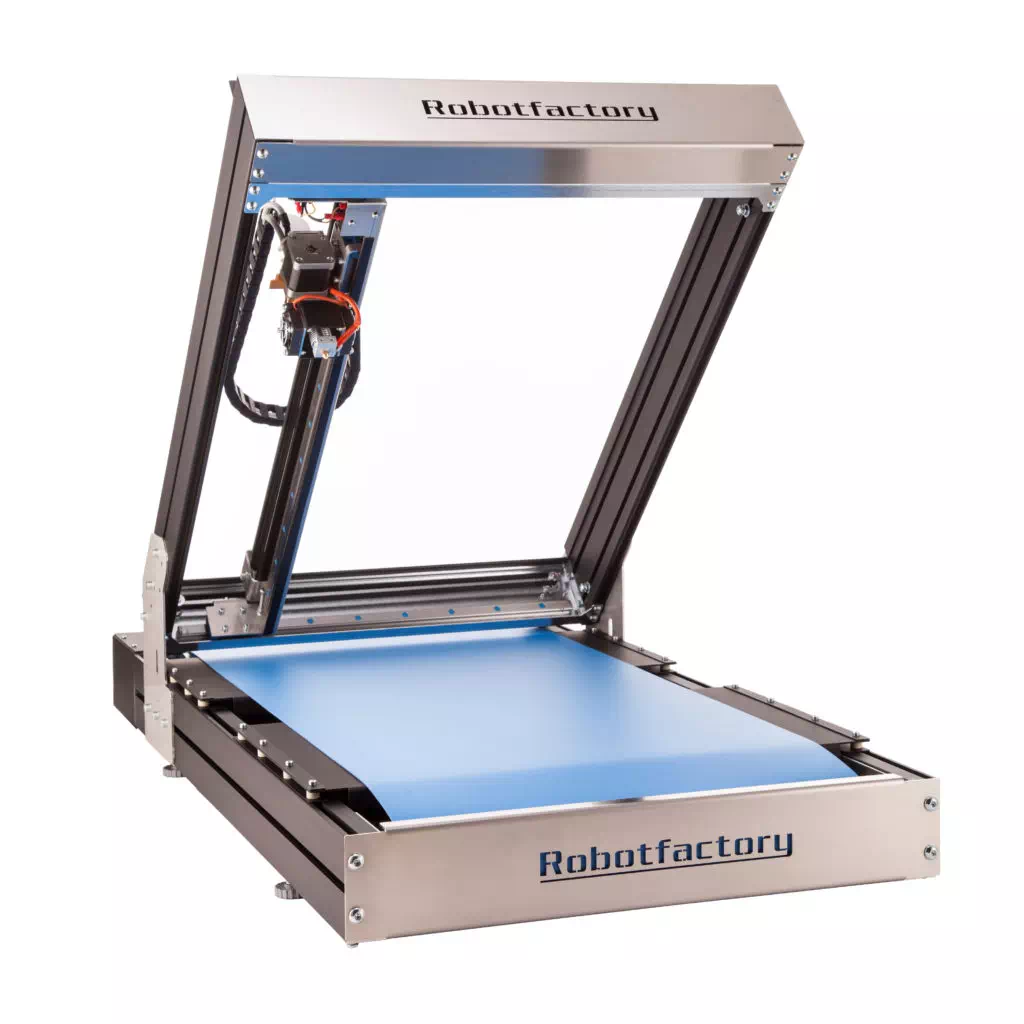

3DL PRINTER - HD 2.0+

3DLPrinter-HD 2.0+ (fourth generation)

HIGH DEFINITION for excellent results and an unrivaled speed.

Building a 3D printer like 3DLPrinter-HD 2.0+ requires more than technology and innovative ideas, an engineering of this type is the result of a philosophy that we always follow with constancy: ensure maximum performance and the best possible longevity to our products.

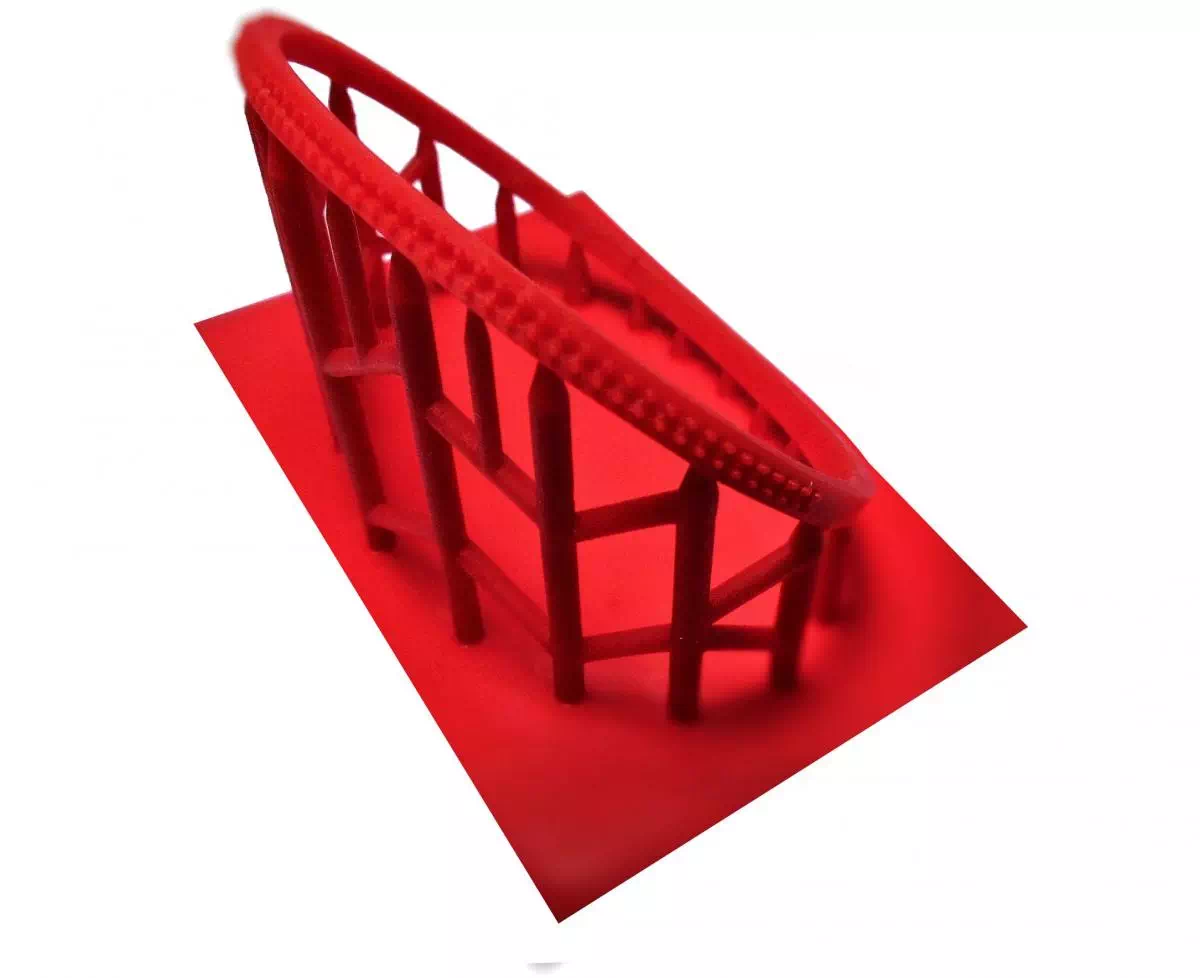

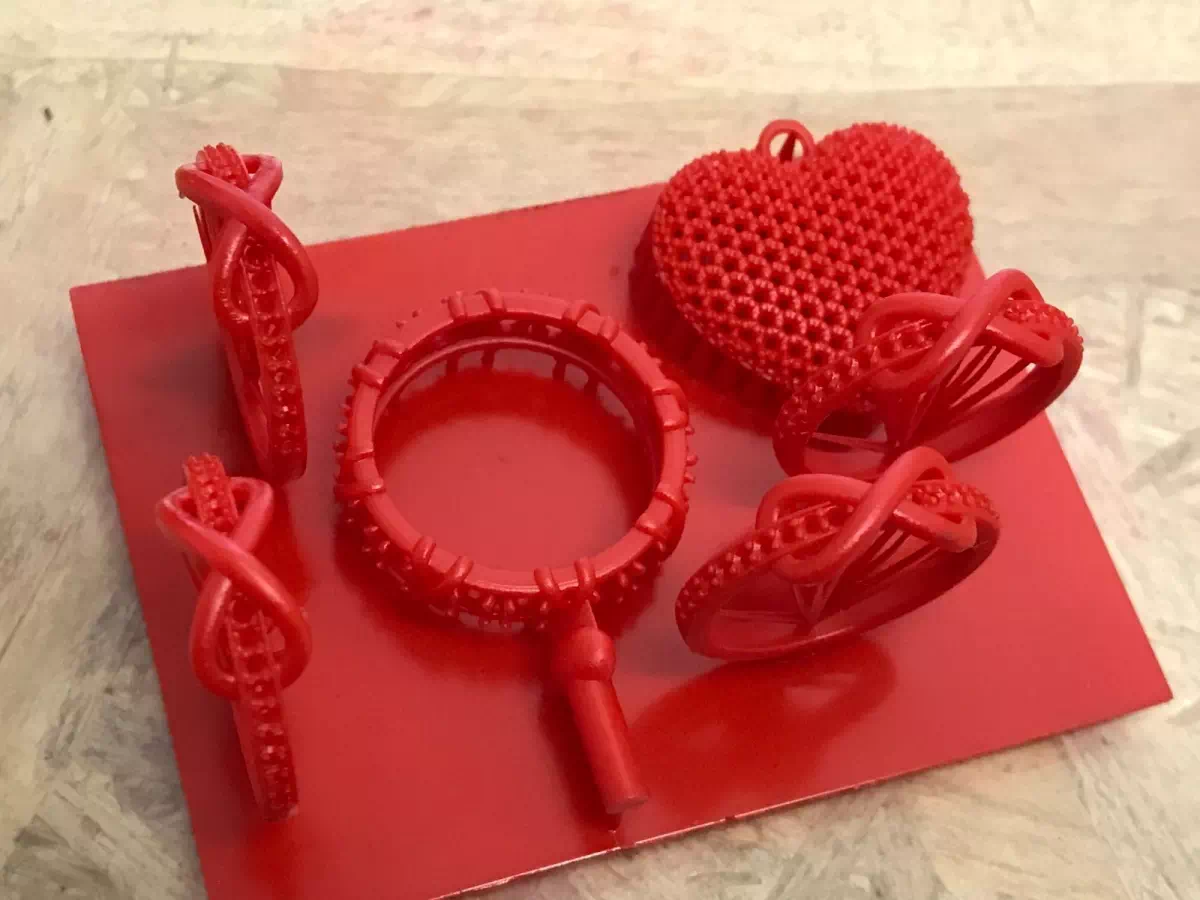

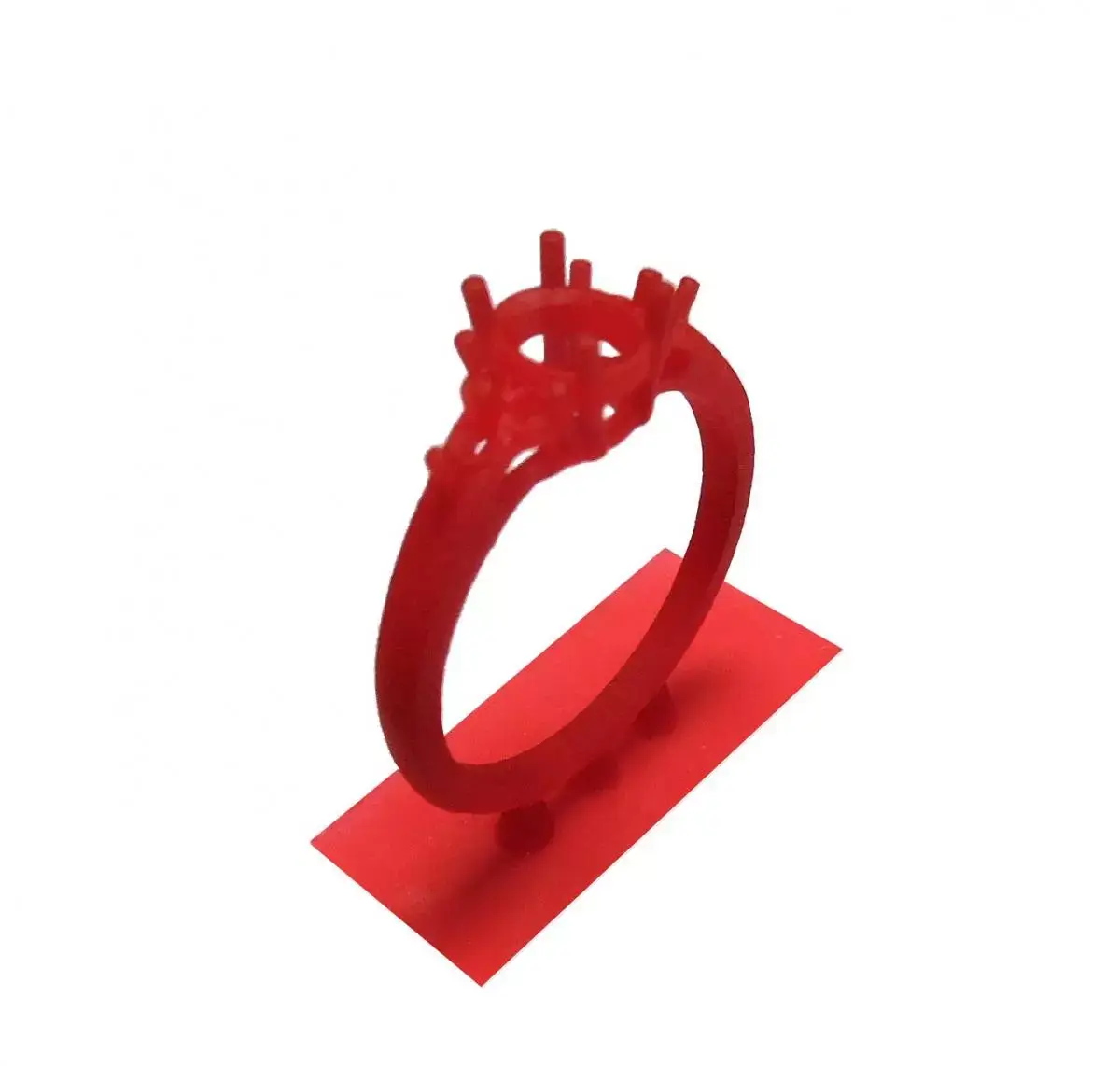

The 3DLPrinter-HD 2.0+ (fourth generation) is a professional stereolithographic printer based on high resolution DLP© technology.

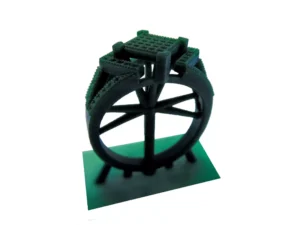

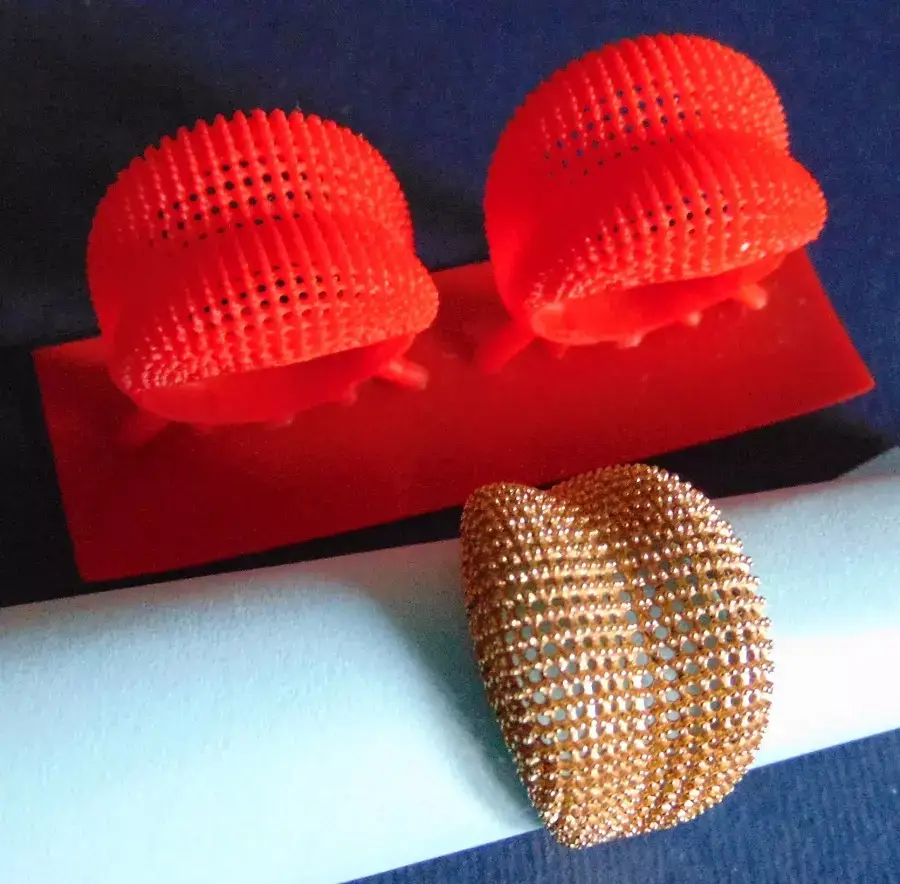

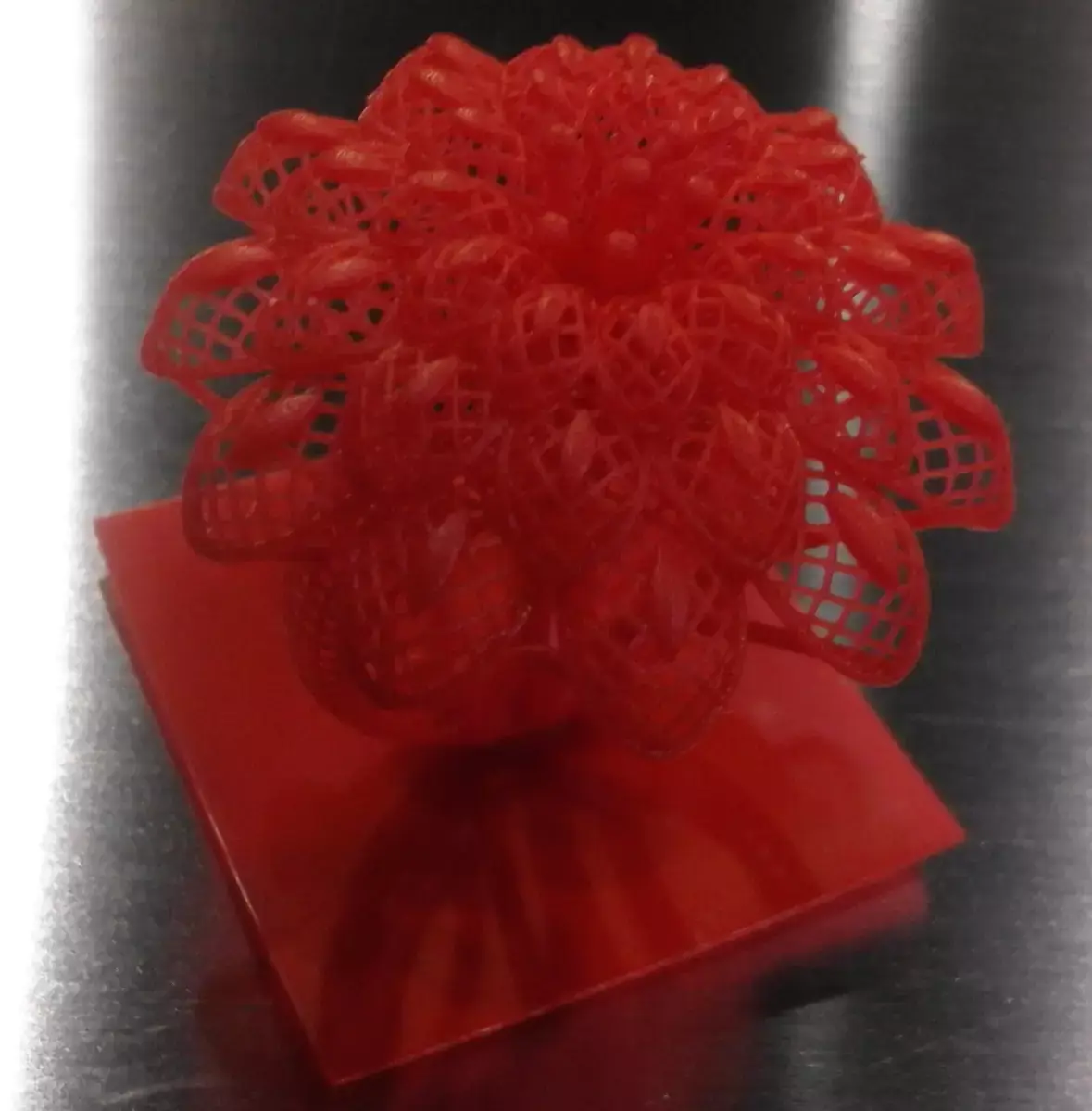

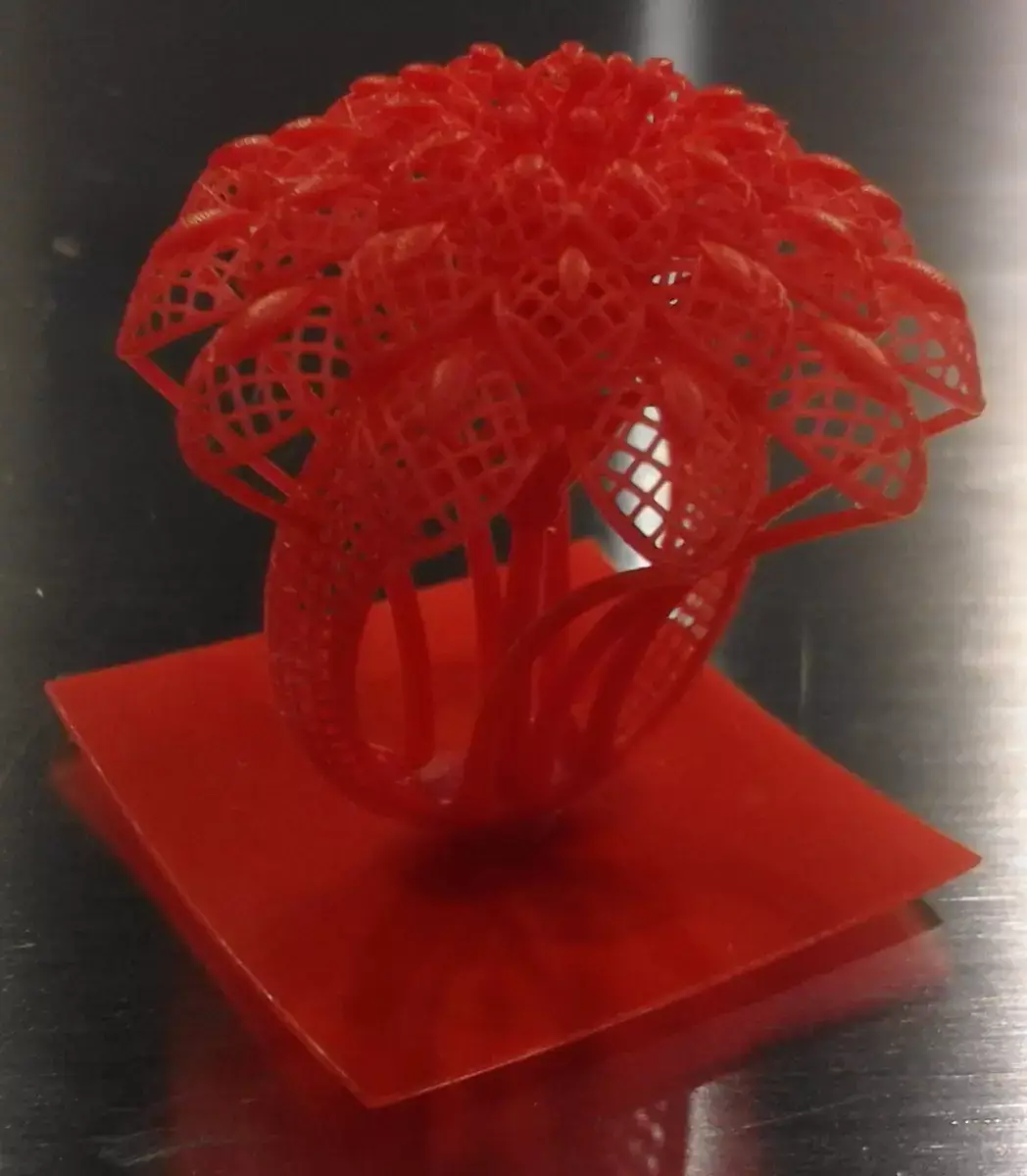

DLP© technology is characterized by speed, precision and resolution that can hardly be achieved with other printing methods. In fact, this technology is particularly suitable for obtaining excellent levels of detail and superficial precision, ensuring accuracy and 3D definition.

The used prototyping technique DLP© is the system of 3D printing that uses photosensitive polymer resin

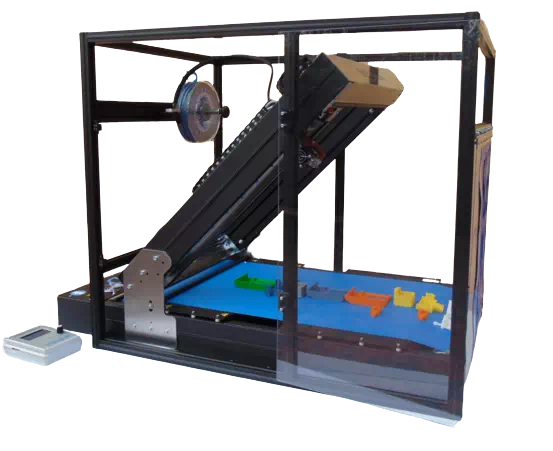

The process is quite simple, a special projector is used to project images in the resin, contained in a vat, which hardens when exposed to light of a certain intensity and wavelength. The projected image hardens a layer of resin at a time, until the entire 3D model has been realized.

To create an object in 3D, you start from a three-dimensional drawing in STL (Standard Tessellation Language), which is a file format available in all 3D CAD systems, therefore, by using the management program that comes in support of our printers, we create a series of images of the sections of the object (layer) which will be projected into the resin through the special projector.

The 3DLPrinter-HD 2.0+ (fourth generation) is able to achieve amazing results, as it allows to achieve an extraordinary surface quality with extremely fine details. The printer keeps the most interesting peculiarity of the previous model, the high speed, obtained through the adoption of a particular movement of the resin vat, which allows a rapid solidification of the whole layer in one operation.

Robot Factory offers a complete system including: printer, accessories, software.

With 3DLPrinter-HD 2.0+ printer are supplied all accessories that you need for printing process:

- Management and printing Software 3DL Printer.

- User Manual.

- Ultrasonic device (for parts cleaning ).

- UV Oven (for part surface hardening).

- Special pliers in plastic (for manipulating objects).

- Plastic spreader (for cleaning the vat).

- Brush (for the cleaning of the vat).

- Steel scraper (for remove the printed piece).

- Pack of moistened napkins (for lens cleaning).

- Pack of disposable gloves (for part handling).

- Polypropylene tray (for tools cleaning).

- Metalic palette (for resin mixing).

- Hex service key of 2,5 mm.

- Pack of paper sheets useful (for initial zeroing).

- Bubble level tool (for printer leveling).

- Plastic box (empty – useful for cleaning).

- Plastic bottle (empty – for take the used resin).

- Package containing two Siligel.

- Roller (for applying Siligel).

- Syringe (capacity 60 ml.) without needle (for remove liquid from ultrasonic device).

- Rechargeable air blower (for dry the printed piece).

- Rubber blower (for remove dirt on projector lens).

- Inox filter (for filtering the used resin).

- Spanner -13 mm (to tighten the adjustable feet).

- Pack of paper towels (for cleaning).

- Little bottle of Shampoo (for application of Siligel).

Robot Factory production is MADE IN ITALY.

HOW TO EVALUATE A STEREO-LITHOGRAPHY – 3D PRINTER

DLP © – Registered trademark of Texas Instruments Inc.

- Technical Specifications

- Media

- Documents & Download

- Info

- Prices

| One-year warranty. |

| Declaration of EC conformity. |

| Support of the tray with contemporary movement of shifting – tilting (this feature is “only” on 3DLPrinter-series). |

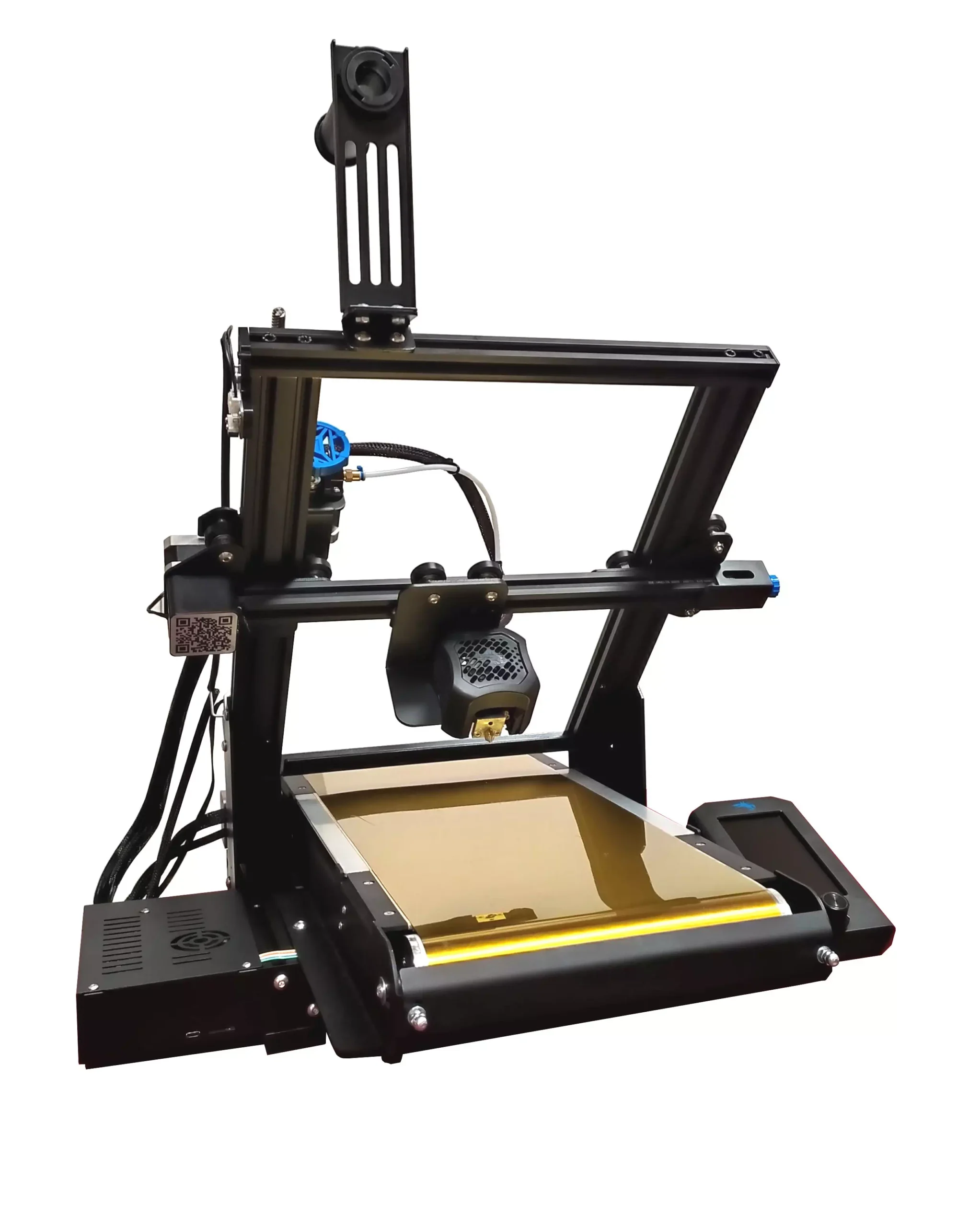

| Supporting structure in steel powder coated in matte black. |

| Prismatic guides with double ball bearing (there are only on professional machines). |

| Z axis with ball screw (there are only on professional machines). |

| Base of the vat in Siligel to allow quick replacement (this function is only on 3DLPrinter series). |

| Construction base of the piece removable for quick cleaning. |

| Base on porcelain stoneware. |

| Coverage – protection in PMMA on ball bearings, with locking (there are only on professional machines). |

| Overall dimensions | 310 x 380 x 710 mm (length, width, height) |

| Weight | 35 Kg approx |

| Printing dimensions | 100 x 56 x 150 mm (length, width, height) |

| Power supply | 230v 50-60 Hz – 400 W approx |

| X – Y resolution | 50 μm (1920 x 1080 Pixel) |

| Z resolution | From 30 μm to 100 μm |

| Input file format | STL |

The prices of the product with related accessories will be provided on request.