BENCHTOP INJECTION MOLDING

The benchtop system for thermoplastic injection molding

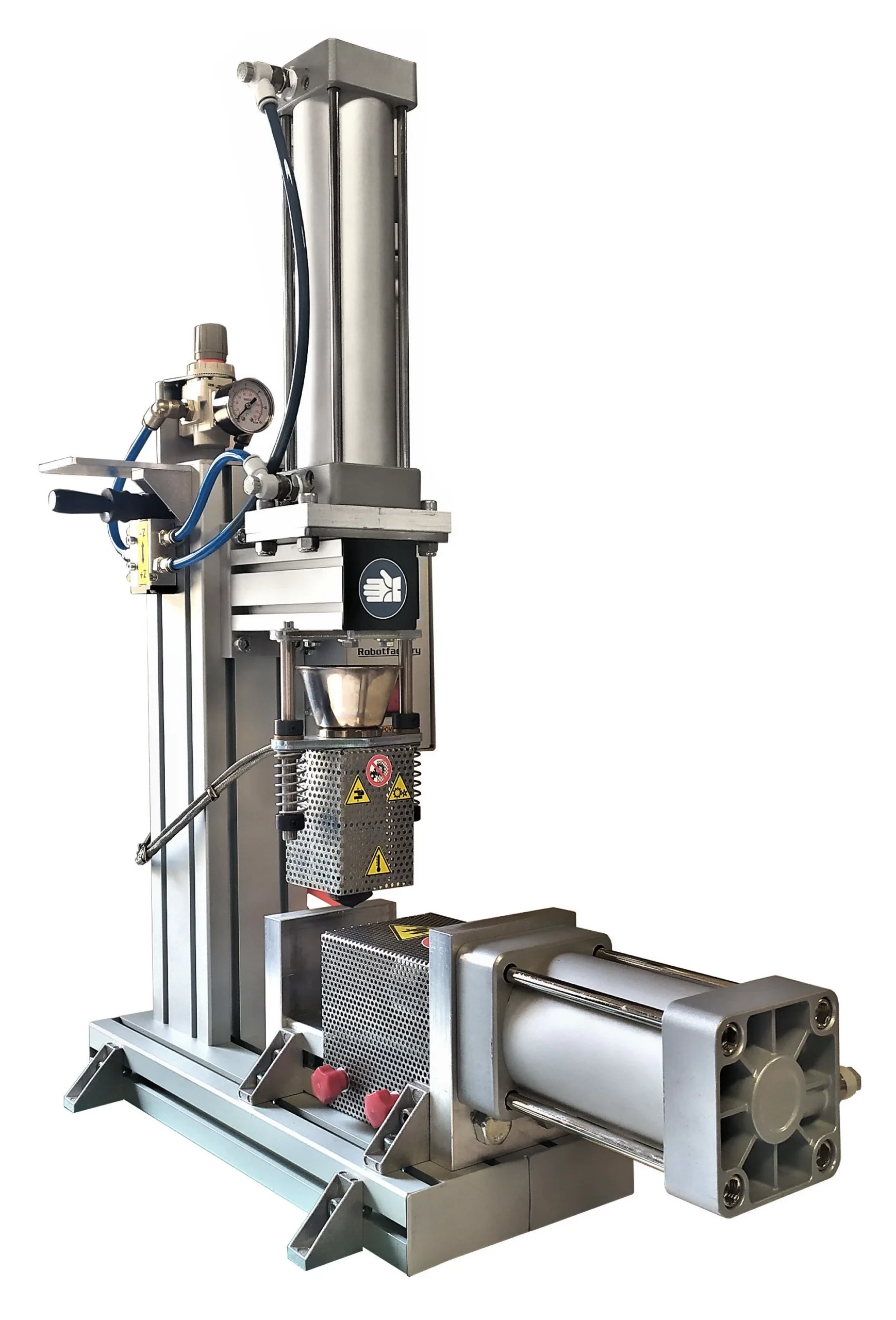

Benchtop Injection Molding is the benchtop system for thermoplastic injection molding developed and manufactured by Robot Factory Srl.

Benchtop Injection Molding is a system designed to inject thermoplastic material into metal molds for prototyping, research and development, production cycles.

The use of Benchtop Injection Molding is perfect for a variety of uses within electronics, jewelry, figurine and medical device manufacturers and other specialized applications that require many small plastic parts.

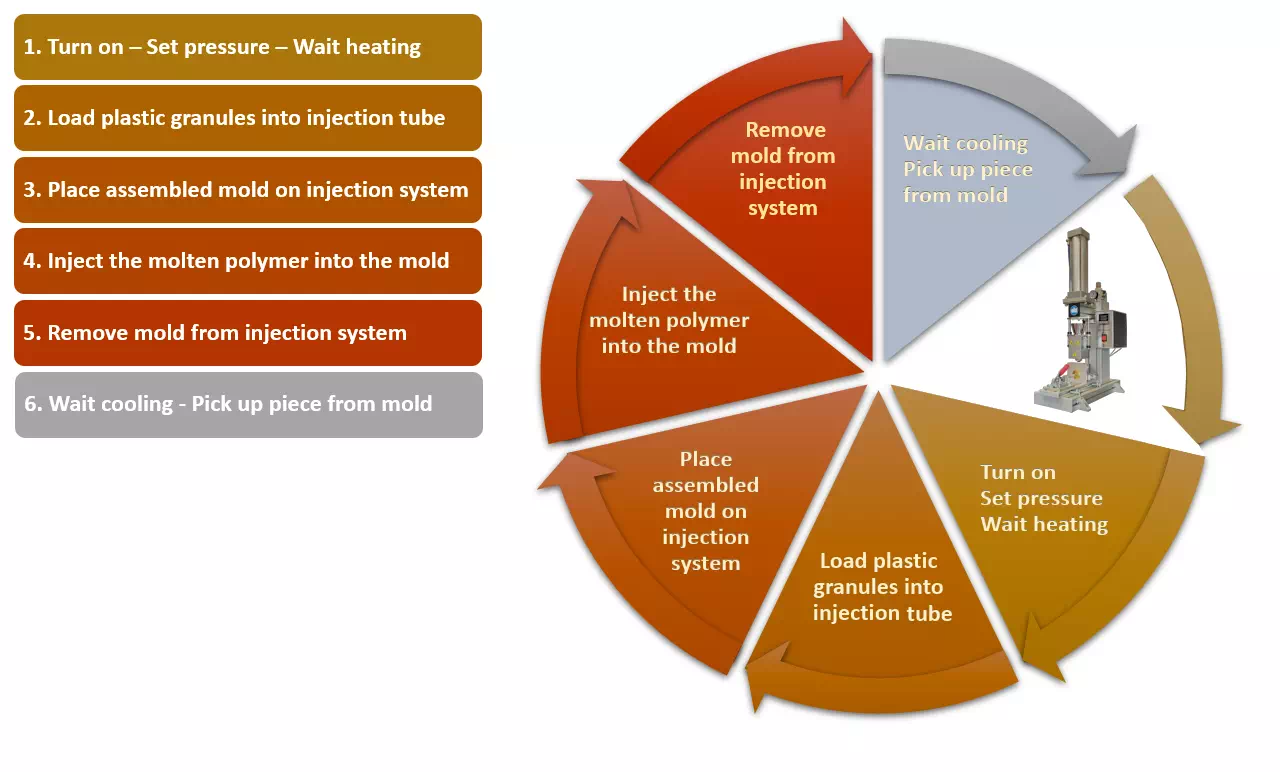

Benchtop Injection Molding is based on a basically simple principle, by heating the loaded plastic in a heating chamber, once the plastic has reached its melting point, it is pressure injected into a two-shell mold

The pressure is maintained for the time necessary to completely fill the mold with the plastic that is injected through the injection nozzle, this causes the plastic to take the shape of the mold. Once the mold is filled, the mold is expected to cool and the piece to solidify completely

Once the piece has solidified and cooled, the two mold shells are opened to be able to take it out.

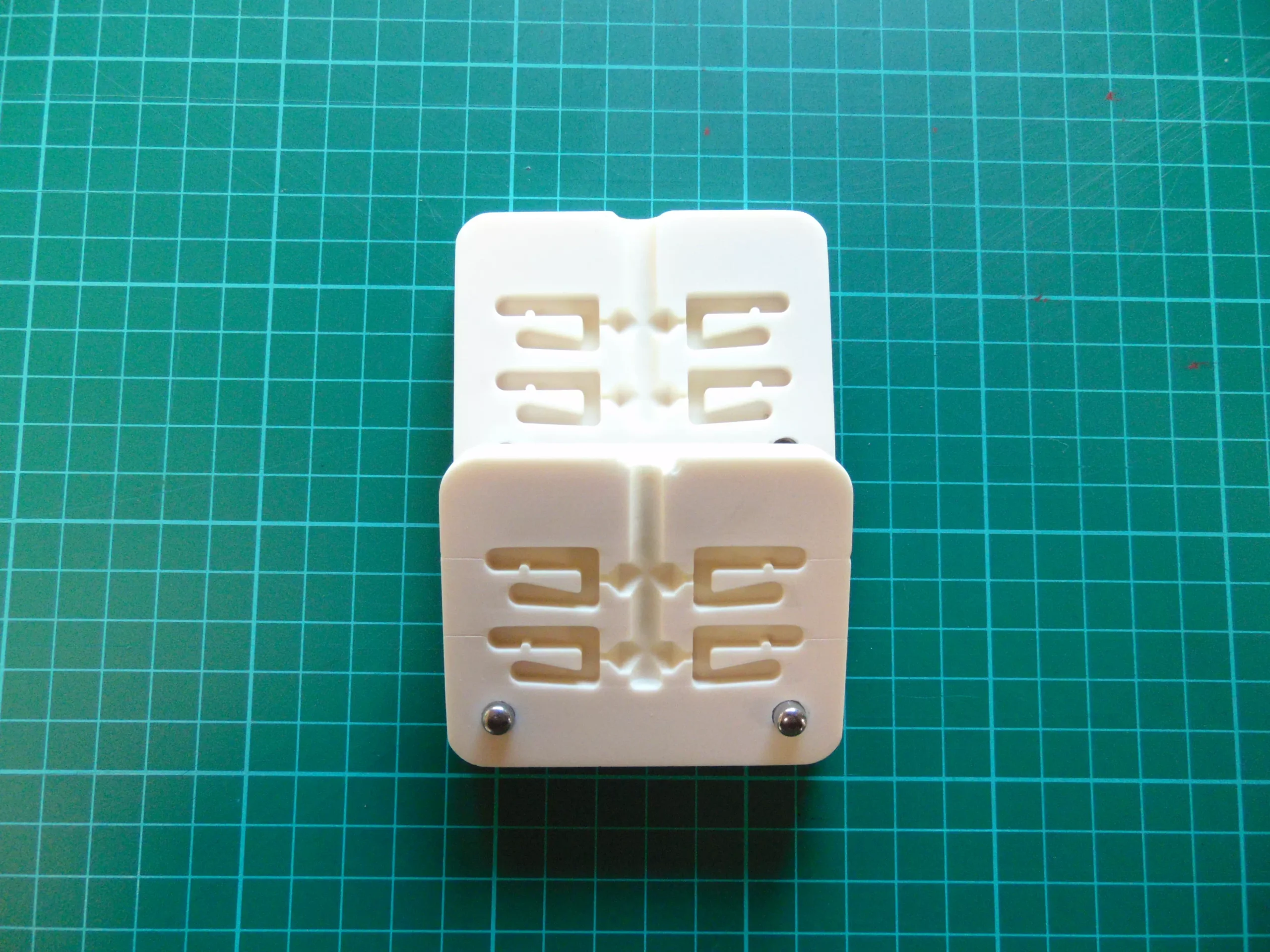

Usually the mold is made up of two aluminum half-molds (obviously the mold can also be made of steel, resin, epoxy resin, etc.).

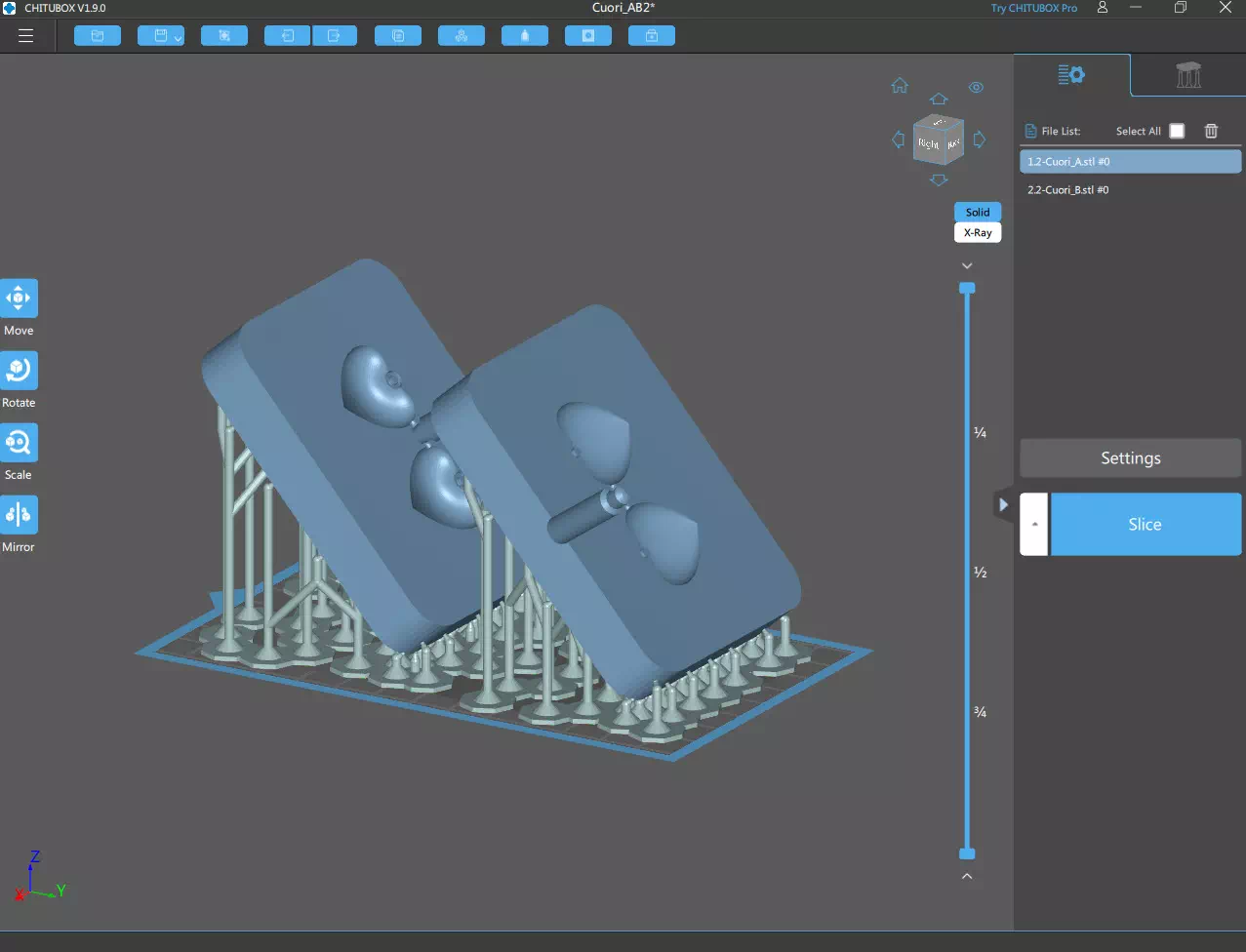

As an alternative to metal molds, the new system developed for making molds with resin can be used.

The resin mold is very easy to make and allows rather high resolutions, in particular there are some high temperature resins on the market with which it works very well even with cheap stereolithographic printers.

As you can guess, the fact of no longer having to make aluminum molds with the CNC, except for those who need large runs, puts this technology in another plane, since for many users it could be a problem to use the CNC.

It is not excluded that the molds produced with 3D printers can be inserted inside aluminum counter-molds.

Some examples of objects made with Benchtop Injection Molding using resin mold

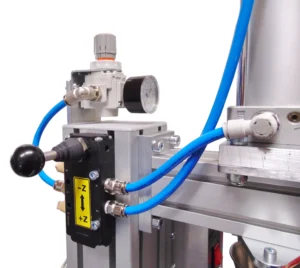

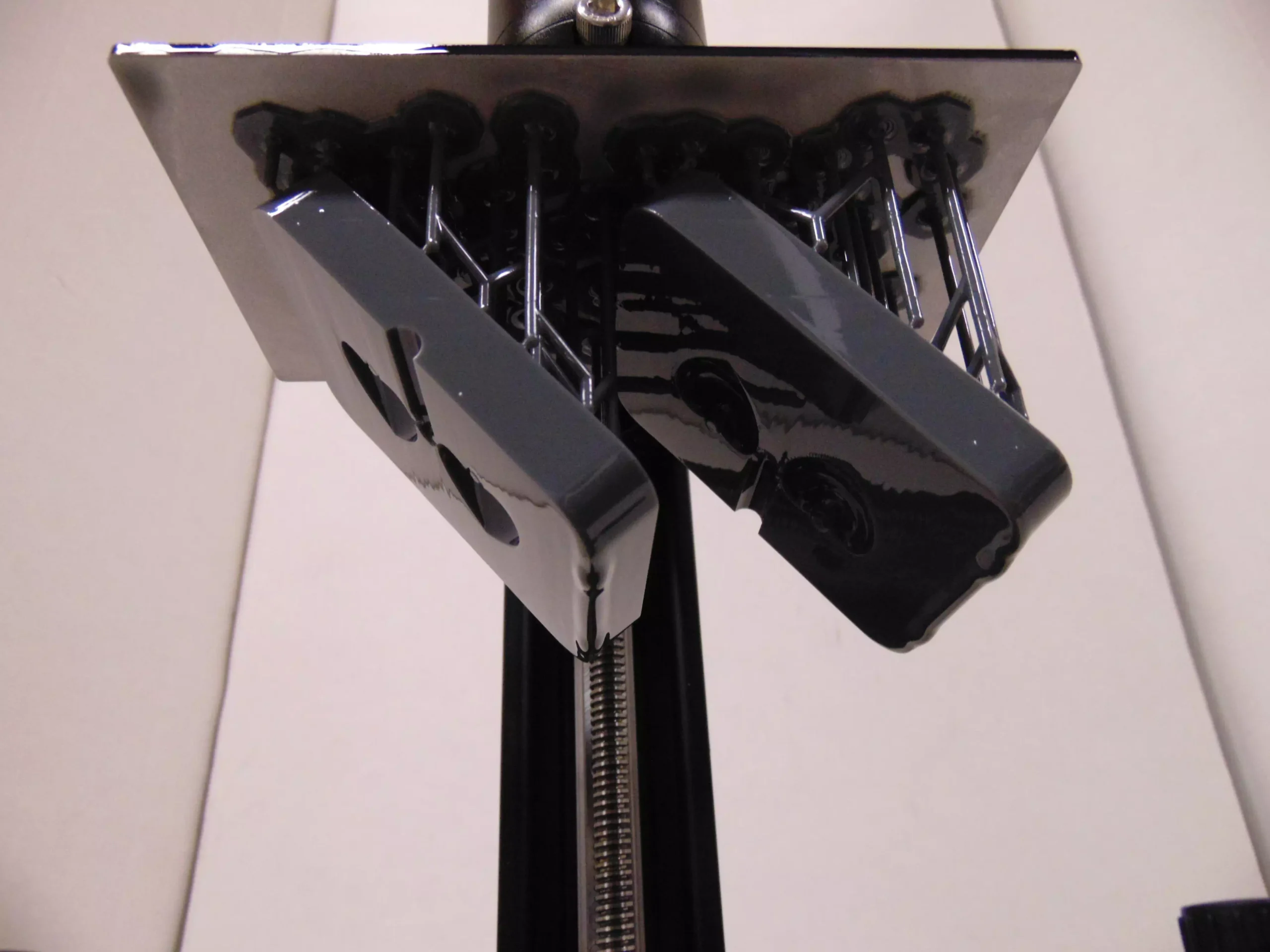

Pneumatic Vice

To complement Benchtop Injection Molding we recommend the use of the pneumatic vice to lock the mold, available as an accessory.

This device is used to block, during the use of Pneumatic Benchtop Injection Molding, the molds composed of two half shells in aluminium, steel, resin, epoxy resin, etc., this to allow an easier and more stable injection operation.

Automatic Injection System (Time Management)

The automatic injection system (time management) is a device which, when used in association with the Pneumatic Injection Molding system, makes it possible to keep the processing times constant for each cycle, thus facilitating and improving the quality of the work.

One of the advantages of this innovative system lies in the possibility of regulating and controlling the injection times, this to achieve maximum repeatability of the processing result.

The system allows you to manage both the timing of the clamp closing and the timing of the descent of the piston for the injection and consists of the following components:

- Vice management solenoid valve (in place of the manual one)

- Piston management solenoid valve (replacing the manual one)

- Two buttons (can be installed in a position to be pressed with both hands)

- Electronic control box (microprocessor, display, emergency button, etc.)

Once installed, the automatic injection system allows you to set the time required to reach the maximum clamp pressure, introducing a delay before giving consent for the injection piston to descend, and keeping the latter under pressure for the set time necessary for correct injection. Once the set time is reached, the piston retracts and the vice also opens with a short delay set by the firmware.

Thanks to its automatic management of processing times, the automatic injection system is able to guarantee a more precise and accurate result, compared to the version of the system in which the management of times is manual, also avoiding waste of material that can be generated when the times of pressure exerted are not well adjusted.

Here is a summary of the setting and usage steps:

- Set the injection pressure (as usual)

- Set the material temperature (as usual)

- Load the material to be used

- Set the vice delay time (necessary only initially)

- Set the injection time (necessary only initially)

- Place the mold

- Give consent for the start of work

- Press both start buttons simultaneously

- Wait for the cycle to complete

- Remove the mold

Repeat steps from 6 onwards for the next cycle and so on.

The automatic system must therefore be set with the right injection and delay times when starting the production of a new process and allows you to have control of the injection times at each subsequent cycle of the same process.

Of course, all the precautions to ensure the safety of the various operations have been implemented in the microprocessor firmware.

The Automatic Injection System is supplied already installed on the Pneumatic Injection Molding system equipped with a pneumatic clamp if required, or it can be supplied in kits to be installed for those who already have Pneumatic Injection Molding.

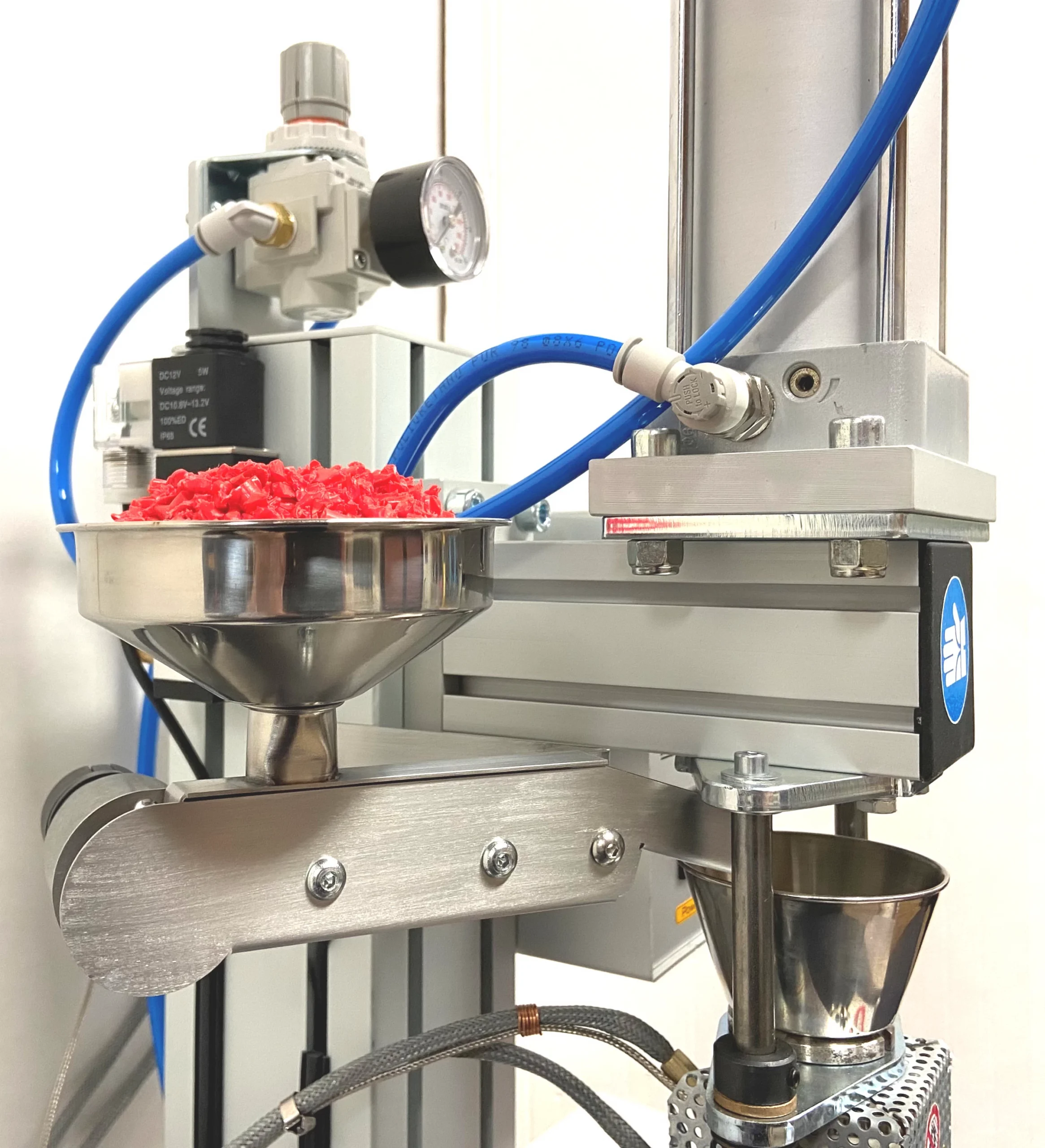

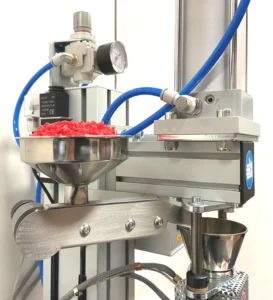

Automatic Material Feed

The Automatic Material Feed is an automatic loading for injection molding. Automatic Material Feed was developed to improve loading operations on Benchtop Injection Molding. This new tool automates the material loading process for injection job, ensuring the efficiency and safety of loading operations.

The Automatic feeding system is another item that is added to the Benchtop Injection Molding universe, making the system increasingly high-performance and competitive in the market.

The use of Pneumatic Injection Molding with Pneumatic Vice in combination with the Automatic Feeding system allows the material to be automatically fed before each injection cycle, giving the possibility of speeding up, facilitating and improving the quality of the work.

The Automatic Feeding system manages, via microprocessor, both the advancement speed of the belt where the material is located and the material loading time, feeding the injection chamber with the necessary quantity.

The Automatic Feeding system consists of the following components:

• Structure for the containment and distribution of the material

• Microprocessor for managing the material feeding system

Installation is very simple and quick and does not require special skills.

The Automatic Feeding system increases production by approximately 20% compared to manual feeding as it eliminates the time needed to load the material.

Using a rotary encoder it is possible to very simply set both the belt advancement speed and the motor operating time, all of which can naturally be viewed on the display on the system.

The Automatic Feeding system can be installed with both Manual Pneumatic Injection Molding and Automatic Pneumatic Injection Molding, but only if the Pneumatic Vice is present since this is what manages the automation.

As an alternative to the Automatic Feeding system, a Semi Automatic system is available which uses the same structure for the distribution of the material. The Semi Automatic Feeding system works by pressing a button located on the electronics container which makes the material flow into the injection chamber until the button is released.

This product has the declaration of EC conformity.

All Robot Factory production is MADE IN ITALY.

- Technical Specifications

- Media

- Documents & Download

- Info

- Prices

| Model | Pneumatic |

| Max processing temperature | 350 °C |

| Temperature processing | Digital (4-digit) with double display (reached, set) |

| Injection chamber capacity | 32 Cm3 (about 32 g by weight at 1.0 density) |

| Injection nozzle | Hole 6.0 mm |

| Mold size dimensions (base) | 80mm L x 70mm H x 40mm T (user adjustable) |

| Pneumatic cylinder size | Ø 63mm |

| Force exerted at 0.6 Mpa | Ø 63mm – 1870 (newton) |

| Operating pressure | Via pressure regulator (recommended 0.6 – 0.8 Mpa) |

| Volts | 230 V – 2 A (fuse 3.15 A – 5x20T) |

| Watts | 340 W |

| Machine weight | 14.00 Kg about |

| Machine dimension | 260mm W x 400mm L x 700mm H |

| Recommended materials | PP, PE, PS, ABS, TPE, TPU, TPV, EVA (also recycled) |

| NOT recommended materials | PC, PMMA, PET, PVC, NYLON, PAxx |

The prices of the product with related accessories will be provided on request.