Robot Factory is…

Andrea Martini, our CEO & Founder, had been making instructional robots and CNC machines since 2002 and used this knowledge to make high quality desktop 3D printers, ‘made in Italy‘.

Since when have you been making 3D printers?

We’ve developed and produced 3D printers, since 2011.

Why did you start?

In the early years, 3D printers had excessive costs and they were the exclusive privilege of big companies. We used our many years of experience in the CNC field, to realize a new goal, to offer affordable professional 3D printers on the market. Today Robot Factory is proud to produce, several high quality and performance 3D printers.

What did you do before?

As early as 2001 Robot Factory designed and produced the first educational robots, equipped with a programmable motherboard, manufactured and sold in assembly kits.

Later, Robot Factory, the first on the market, created a CNC system to be assembled, with the aim of making the use numerical control machines available to an increasingly wider public.

Since 2002 for several years Robot Factory has designed, produced and sold several CNC systems, mostly produced and distributed in assembly kits.

What kind of systems do you make?

The first 3D printer that we developed, was the 3D-ONE (material extrusion 3D printer, manufactured and sold until May 2014), since May 2013 we started the production of the 3DLPrinter series (stereo-lithographic printers) followed by the 3DLPrinter-HD models.

Today Robot Factory manufactures and sells three different models of 3D printers:

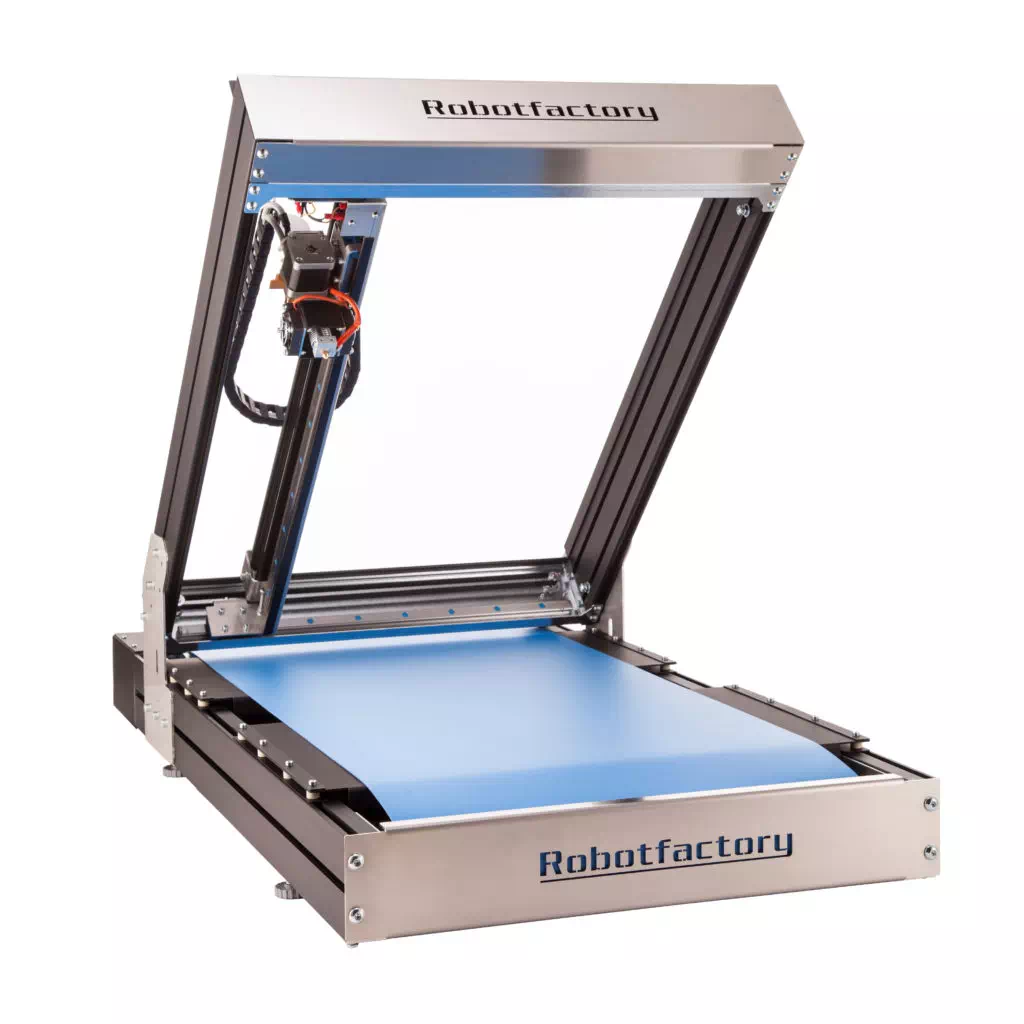

Sliding 3D – is the professional FFF (Fused Filament Fabrication) 3D printer equipped with an “infinite” printing plan, that makes this 3D printer particularly suitable both for serial production of small items as well as for 3D printing of very long objects (theoretically unbounded in length). The most distinguishing feature of Sliding-3D is the build volume (410mm x 380mm x ∞ – endless), because the printing plane is a sliding belt, this means it can be engaged in an “uninterrupted” work cycle.

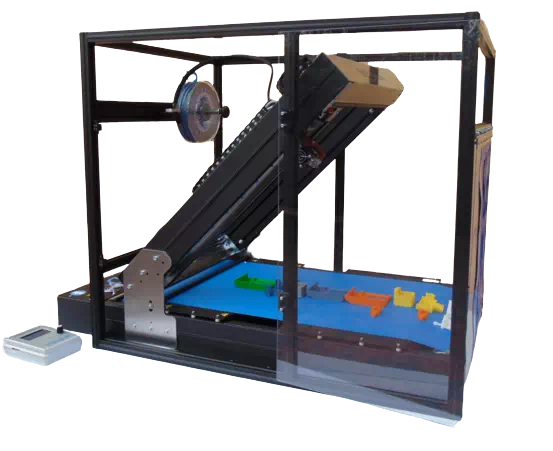

After several successful projects produced and sold in kit since the first years of our activity and using our long-lasting experience in the 3D printer industry, from november 2019 we’ve offered the 3D Silver Belt, FDM-45 3D printer equipped with the sliding printing bed and the 45° inclined extruder, achievable through an “all-metal mounting kit”. The first and only one kit to assemble a 3D printer that does not require plastic parts previously printed!assemblare una stampante 3D che non richiede parti in plastica precedentemente stampate!

It’s still in production, now at its fourth generation, the 3DLPrinter-HD 2.0+ our stereolitographic 3D printer with DLP © technology that uses a special photosensitive polymer resin to create objects – high definition printing details.

Besides in the last years we developed and produced some interesting projects, melding 3D Printing technology with other production methods, that can be good alternatives to 3D Printing, as well as complement it. For example, the desktop thermoforming 3D Forming

Benchtop Injection Molding is the benchtop system for thermoplastic injection molding developed and manufactured by Robot Factory Srl.

Benchtop Injection Molding is a system designed to inject thermoplastic material into metal molds for prototyping, research and development, production cycles. The use of Benchtop Injection Molding is perfect for a variety of uses within electronics, jewelry, figurine and medical device manufacturers and other specialized applications that require many small plastic parts.

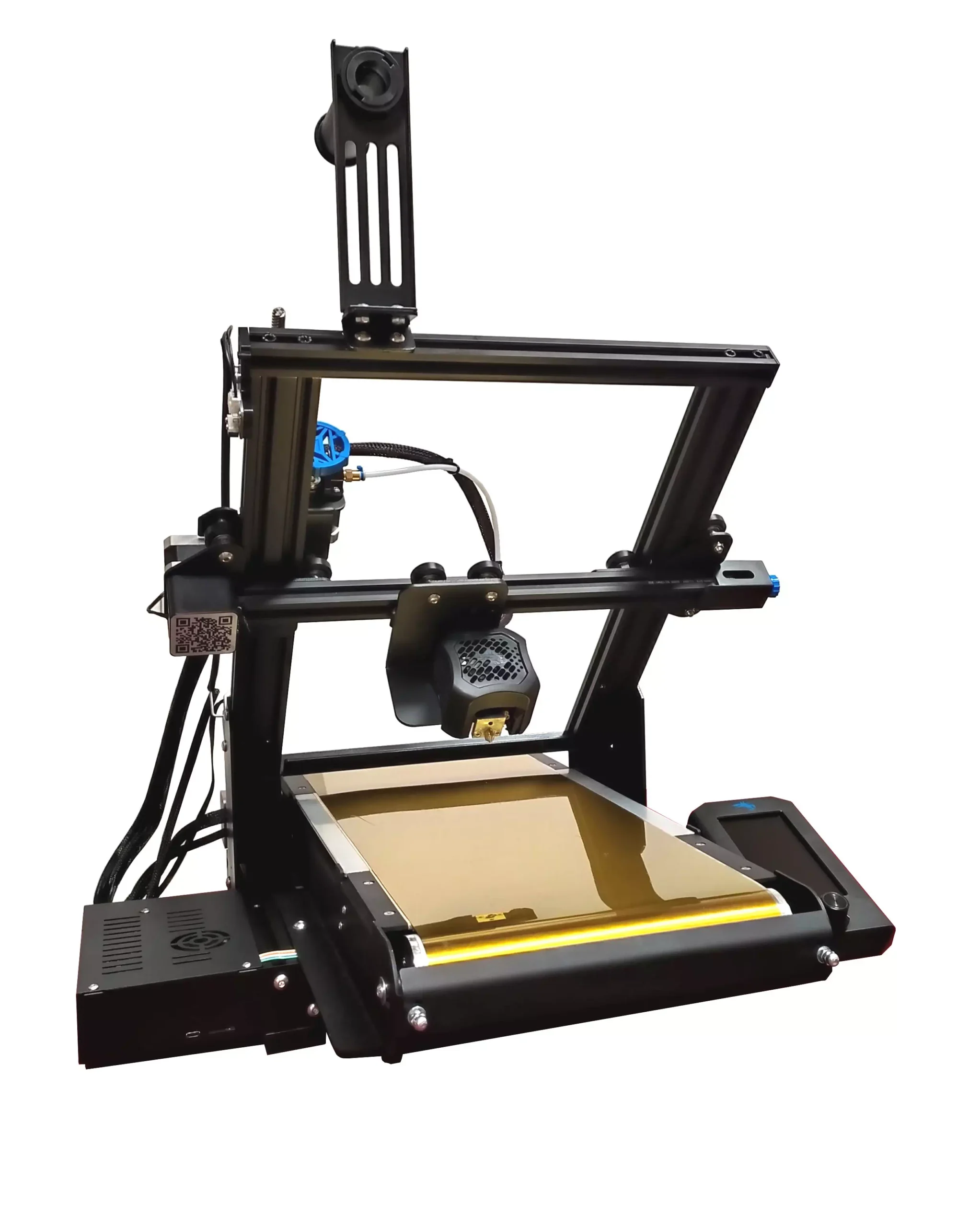

Steel Roller and Steel Roller 45 kit are the expansion kits developed and produced by Robot Factory Srl, for the upgrade of a printer to allow continuous printing.

The kit, in both cases, consists of various parts to install a stainless steel conveyor belt that replaces the print bed of the printer on which it is mounted. In the case of Steel Roller 45 kit, the upgrade allows to generate the printing layers are generated inclined by 45° to the printing bed, this feature entails multiple advantages compared to any other traditional 3D printer.

Your systems convey a robustness idea…

We do everything it’s possible to ensure that every 3D printer produced by us it is engineered to the highest standards, beyond what is required by any national and international certification. We make machines engineered with extreme care in the mechanics and electronics contained in them, resulting in particularly solid, accurate and long-lasting 3D printers.

Who are they meant for?

At Robot Factory we have always been aware of the strategic value of the investing in the future. As proof of this, the many projects developed in the course of our long experience. We are continuing, year after year, spending our energies on innovative, new projects, that result in products, engineered with the utmost attention to detail, meant to be valid and durable instruments in successful contexts. Our 3D printers are meant for production of concept and functional prototypes, manufacturing tools, replacement parts, designer support tools, etc.

How do the sliding 3D printers work?

The most distinguishing feature of our sliding belt 3D Printers, both the “Sliding-3D” (Standard and Plus) and Silver Belt, is the endless Z-axis, which means you can handle an uninterrupted work cycle to make prints of various 3D objects, with any 3D print length that you can imagine. Here it’s how these 3D printers work: the machine is a non-orthogonal coordinate system in which the construction plan does not coincide with the adhesion plan of printing object. The X-Y plan is inclined on the Z axis. So, it prints any layers to a fixed angle from the Z axis. This feature, along with Z axis that is a moving belt, it allows the build platform shifts itself continually with respect to the extruder. This one is inclined in turn (at a fixed angle) relative to the build platform. Thus this system allows to print ‘in a continuous way’.

What kind of customers do you have?

Actually we have always had customers who make professional use of our machines, medium-large companies and some craftsmen who have evolved in their work by adopting the new technologies to support their work process. With this last project, Silver Belt kit, we reduced the purchase costs for the end customer and make the machine easily transportable, thus also we reduced the shipping costs, only in this way we can easily reach anyone who wants to take advantage of the great opportunities of the continuing 3D print, all over the world!

If the skilled user wants to know his 3D printer in all the details, and at the same time he wants to take advantage of the great chances offered by the use of the FDM-45 technology, using the “Silver Belt” kit he will have the opportunity to build a 3D printer that has the functional features of the “Sliding-3D” professional printer, but it let the expert user the ability to modify each part according to own needs! …and when the user finally will use Silver Belt, the experience will be much more rewarding, since he will really know every detail, but with the guarantee that every part has been perfectly engineered taking advantage of Robot Factory solid experience in developing this innovative technology.

Why to buy a printer from Robot Factory?

Because we believe in the great potential of this industry, but we know and understand the concerns of who approaches new technologies and we would never build anything in which we do not believe 100%. Because any of our products is the result of a philosophy that we always follow with constancy: ensure maximum performance and the best possible longevity to our products.

Who is buying them?

This technology can create accurate functional prototypes, manufacturing aids, customized objects, medical aids, parts for design checks, including for mechanical engineering, because it is suitable both for serial production of small items as well as for 3D printed long objects.

Our customers are:

- specialized partner companies to completely follow the customer’s projects, from the initial idea to the delivery of the finished product;

- companies engaged in the manufacture of measurement and regulation equipment, precision instruments, production tools;

- companies engaged in the automotive industry;

- companies that produce components for the domestic appliance sector;

- some of our customers develop and produce functional parts, components and engineering systems for machines and plants, for mining, the automotive industry and other important industrial branches;

- companies that performs services and spare parts production for Aerospace industry;

- companies that produce packaging systems;

- companies that design, assemble and commercialize hardware for various fields.

What kind of parts do they make?

Our customers make: concept and functional prototypes, manufacturing tools, replacement parts, designer support tools, etc.

What is the advantage?

Using Sliding-3D or Silver Belt, when a continuous printing batch is running, any time that a job is completed, a new job starts automatically and the printing goes on. During the printing job the belt goes forward until the printed object, reaching the front roller, detaches itself from the same belt. In this way, the items can be collected in a container in front of the roller.

Exploiting at the same time the endless print bed, the inclination of the printing layers and the layers translational function, Sliding-3D and Silver Belt can reduce up to 100% the support structures (for the ‘overhangs’) usually needed to print using the other 3D printers. This means the extraordinary benefit of saving time and material used for the same print and drastically reducing post-processing times (usually required for the removal of any support structures and for the finishing of the printed part).

Sliding-3D has a special print bed made using a composite material, it does not require any preparation (glue, spray, adhesive belt, etc.), because it prevents the possible detachment of the model during the printing phase and favors the detachment at the end of printing phase. In addition, it’s available a special “Box” for protection and insulation, engineered to ensure compliance with the functional characteristics of the Sliding-3D printer. The “Box” creates a printing environment that is isolated respect to the place where the printer is used, both for temperature and for dust.

All Robot Factory production is MADE IN ITALY.