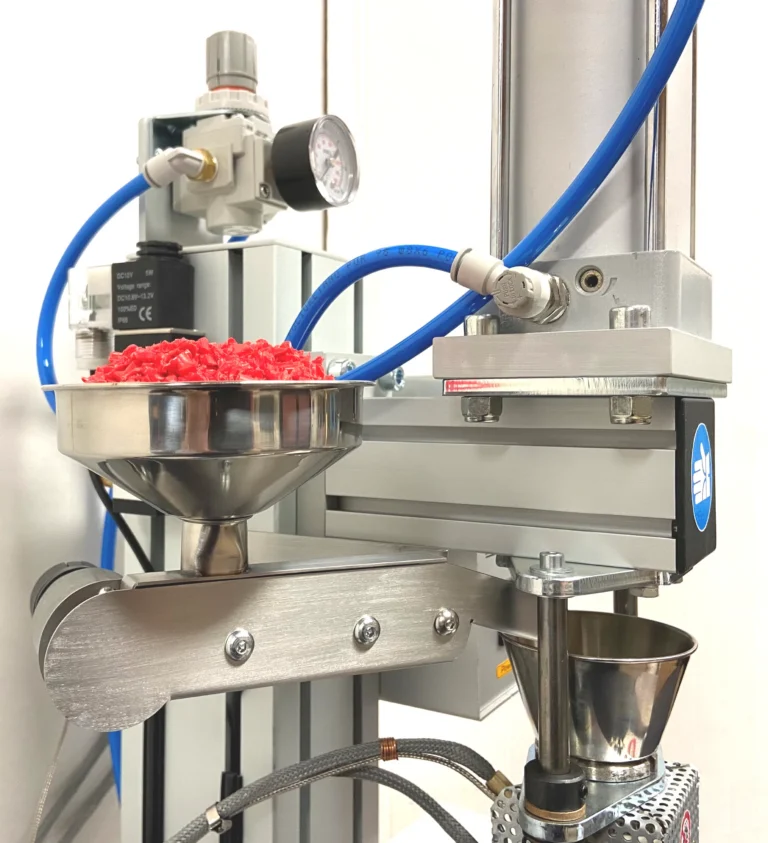

Automatic Material Feed is an automatic loading for injection molding. Automatic Material Feed was developed to improve loading operations on Benchtop Injection Molding. This new tool automates the material loading process for injection job, ensuring the efficiency and safety of loading operations.

The Automatic feeding system is another item that is added to the Benchtop Injection Molding universe, making the system increasingly high-performance and competitive in the market.

The use of Pneumatic Injection Molding with Pneumatic Vice in combination with the Automatic Feeding system allows the material to be automatically fed before each injection cycle, giving the possibility of speeding up, facilitating and improving the quality of the work.

The Automatic Feeding system manages, via microprocessor, both the advancement speed of the belt where the material is located and the material loading time, feeding the injection chamber with the necessary quantity.

The Automatic Feeding system consists of the following components:

• Structure for the containment and distribution of the material

• Microprocessor for managing the material feeding system

Installation is very simple and quick and does not require special skills.

The Automatic Feeding system increases production by approximately 20% compared to manual feeding as it eliminates the time needed to load the material.

Using a rotary encoder it is possible to very simply set both the belt advancement speed and the motor operating time, all of which can naturally be viewed on the display on the system.

The Automatic Feeding system can be installed with both Manual Pneumatic Injection Molding and Automatic Pneumatic Injection Molding, but only if the Pneumatic Vice is present since this is what manages the automation.

As an alternative to the Automatic Feeding system, a Semi Automatic system is available which uses the same structure for the distribution of the material. The Semi Automatic Feeding system works by pressing a button located on the electronics container which makes the material flow into the injection chamber until the button is released.

GET INFORMED NOW!